In Autumn 2015, I contacted Emerald Guitar owner and master builder, Alistair Hay, about constructing a mandolin/12-string/6-string combo for me. A couple of years earlier, Alistair had constructed a doubleneck guitar (a Chimaera model) for me with both necks being baritone-scale lengths and the 6-string side being multi-scaled (with fan frets) as well as an internal RMC unit for MIDI output. This particular build was extremely resonant and very comfortable to play. In addition, the first Emerald Guitar instrument I had owned was an Amicus, which was also very resonant (and loud) given its small body size and body depth, so I was very happy with both instruments.

At the time I communicated with Alistair, I had been playing guitar for about 36 years but up to just a few years prior, I would only play dreadnaught guitars that were constructed out of wood. I got introduced to Emerald Guitars by first coming across an Emerald Amicus and later, an X20 here in the States. I was surprised with respect to the tonal resonance of the carbon fiber tops and really liked the tone and feel.

At the time I communicated with Alistair, I had been playing guitar for about 36 years but up to just a few years prior, I would only play dreadnaught guitars that were constructed out of wood. I got introduced to Emerald Guitars by first coming across an Emerald Amicus and later, an X20 here in the States. I was surprised with respect to the tonal resonance of the carbon fiber tops and really liked the tone and feel.

As a bit of background, in addition to being a musician, I have a background in biology and physics. Over the years, I have tried to “scientifically” understand why the carbon fiber sound is so much louder and somewhat tonally “different” than wooden instruments (carbon fiber sounds a bit warmer to me). I have even performed myriad analysis of field test recordings I have made to compare wood to carbon fiber by examining sound wave properties and sustain. I attribute these qualitative differences to the carbon fiber matrix itself and the individual carbon fibers resonating and vibrating in unison through the process of being unified with resin. In addition, I imagine the offset sound hole must be contributing the top vibrating within the upper bout where the sound hole is absent with increased tensile strength (increased vibration and sound). I believe the biological part must be in the ear of the beholder, as there is a difference between the sound of a wooden guitar versus a carbon fiber guitar, and I have come to prefer the sound of my Emerald guitars. I also live in the Midwest and have found these guitars to be unaffected by the extreme changes between hot, humid summers and cold, dry winters.

In considering the new build, I noticed that the body depth on both my Amicus and Chimaera models were about the same. I did primitive mockups on Photoshop followed by amateurish measuring and made a cardboard cutout from cardboard (actually, thin soda cases) of how this may actually all fit together as a triple neck. I based my assessment on the width and depth of a triple neck guitar as estimated by the Amicus and Chimaera body dimensions. My concern was the width of the body and comfort of my right arm in wrapping around the body for strumming. I am tall (6’3”) and, luckily, my arm fit comfortably using the same shallow depth of the Amicus and Chimaera models with the overall wider body. However, given I am not a designer, fabricator, or luthier, I needed to get an honest opinion from someone with expertise in these areas.

In considering the new build, I noticed that the body depth on both my Amicus and Chimaera models were about the same. I did primitive mockups on Photoshop followed by amateurish measuring and made a cardboard cutout from cardboard (actually, thin soda cases) of how this may actually all fit together as a triple neck. I based my assessment on the width and depth of a triple neck guitar as estimated by the Amicus and Chimaera body dimensions. My concern was the width of the body and comfort of my right arm in wrapping around the body for strumming. I am tall (6’3”) and, luckily, my arm fit comfortably using the same shallow depth of the Amicus and Chimaera models with the overall wider body. However, given I am not a designer, fabricator, or luthier, I needed to get an honest opinion from someone with expertise in these areas.

I communicated with Alistair about my idea and shared I had wanted to own a mandolin again, as I had sold my mandolin along with a bunch of other folk instruments (bouzouki, kantele, hammer and Appalachian dulcimers) to finance some recording gear. I also thought having the mandolin/12-string/6-string combo on one instrument would add some wonderful opportunities for creativity, given my appreciation for open tunings and the fact I would be using the instrument for use in the recording studio.

After going back-and-forth with Alistair a few times, he advised me how this would best work. The triple neck guitar was commissioned at the end of November 2015 with Alistair advising it would be a year or more until he could even get to working on the final design elements and eventual fabrication of the instrument. My hope was I would be able to receive the guitar sometime in late 2017 or mid-2018 (I am familiar with custom luthier builds requiring one to get in line with other builds already commissioned).

After going back-and-forth with Alistair a few times, he advised me how this would best work. The triple neck guitar was commissioned at the end of November 2015 with Alistair advising it would be a year or more until he could even get to working on the final design elements and eventual fabrication of the instrument. My hope was I would be able to receive the guitar sometime in late 2017 or mid-2018 (I am familiar with custom luthier builds requiring one to get in line with other builds already commissioned).

As time progressed with the build, and as it sometimes occurs, questions, ideas, and afterthoughts arose with the custom build. Alistair and I continued discussions about topics that included the electronics on the guitar, scale lengths, neck widths, and MIDI leading up to spring and summer 2017. Another thing we had to consider was whether we would be going with a carbon fiber top or a woody veneer. At the time, I was torn on using a red-stained white limba top or custom painted carbon fiber Celtic art top. I love Celtic art and I was vacillating between having airbrushed Celtic fantasy artwork also mixed with artwork from the Book of Kells. My indecision also contributed to delaying the turnaround somewhat, as I really liked a test stain Robbie at the Emerald shop did for me using red stain over white limba.

Towards the end of 2017 and early 2018, we settled on a full carbon fiber body build with Celtic artwork. We also eventually decided to use the red stained limba for a different build Alistair was also working on for me. I provided Alistair with some examples of artwork I had used on other album projects for reference as well as some artwork I liked from the Book of Kells. We also decided to incorporate three separate outputs rather than any stereo output combos as well as an internal RMC for the 6-string neck.

During June 2018, Alistair and I were able to Skype, as he was preparing to do the mold and complete the instrument for late summer. The only potential issue we were running into was the airbrush artwork. The airbrush technique would not look that great with the fine detail in the artwork and images I had shared. Alistair was trying to find a different artist to complete the fine airbrush artwork but it was proving problematic. I shared I was completing my 2018 release Storyteller and was hoping to have Storyteller out by the end of summer/early fall. Alistair and I discussed some of the artwork I was using for Storyteller but it would not really work for the build.

During June 2018, Alistair and I were able to Skype, as he was preparing to do the mold and complete the instrument for late summer. The only potential issue we were running into was the airbrush artwork. The airbrush technique would not look that great with the fine detail in the artwork and images I had shared. Alistair was trying to find a different artist to complete the fine airbrush artwork but it was proving problematic. I shared I was completing my 2018 release Storyteller and was hoping to have Storyteller out by the end of summer/early fall. Alistair and I discussed some of the artwork I was using for Storyteller but it would not really work for the build.

We mutually considered scrapping the build during the summer, as I was juggling quite a lot at the time and I thought it might be better to reassess before moving any further. In addition, Alistair was set to complete a different guitar build for me at the time that was not quite as complicated and was an instrument I could use for some instrumental guitar writing I was planning.

In September, I completed Storyteller for an October 8 release and immediately began working on an instrument acoustic guitar project I had wanted to do for many years. At this time, my dad became very ill with pneumonia and had a heart attack. While in the hospital, his condition only worsened and was given days to weeks to live, which quickly turned to days to hours. My dad passed away on October 6, 2018 after being in hospice for four days. At this point, I was leaning towards cancelling the triple neck and using the funds I had already applied years earlier.

Before my dad died, he told my mom he wanted his ashes scattered in Dublin, as he was born and raised in Dublin, Ireland (my mom was also born in Kildare, Ireland). I told my mom I would take care of his ashes being scattered and would do so before the holidays and the weather got too cold or it snowed in Ireland.

Before my dad died, he told my mom he wanted his ashes scattered in Dublin, as he was born and raised in Dublin, Ireland (my mom was also born in Kildare, Ireland). I told my mom I would take care of his ashes being scattered and would do so before the holidays and the weather got too cold or it snowed in Ireland.

I figured since I was going to Ireland, I would let Alistair know I was going to be visiting family and learn if I could stop by the shop after six years of emailing/Skyping with him (we had never met). Alistair and I spoke about everything going on and he asked about the artwork for the new instrumental acoustic guitar project I was working on for release in 2019. I described the artwork (and eventually emailed him the artwork to review) and he said he had an artist who could do the artwork to match the parchment illustrations for the album with a Book of Kells theme but it would have to be painted, not airbrushed. I was completely fine with this change and was really happy to get the triple neck back on track and possibly see it in progress while visiting Ireland. It also felt “good” to have something creative like this back on my radar as it was a project we already invested a great deal of time on climaxing at such a difficult time in my life. Moreover, there had been so much loss and change in my life that the influx of creativity from writing, recording and the build itself provided a steady stream of endorphins, which I was emotionally and physically lacking.

Alistair and I also communicated about the instrumental album concept and various song titles I was using. I had one track I was working on I was dedicating to my dad called “A Chuisle Mo Chroí,” which is Gaelic for “Pulse of my heart.” Those words were part of the eulogy I delivered for my dad in Gaelic during his funeral mass in Chicago, so it meant much to me, as did a number of other titles for the project. I sent Alistair all the song titles and information regarding the concept behind the album.

I let Alistair know I would be in Ireland in mid-November and leaving to fly back home on Thanksgiving. Alistair and I were able to work out time for me to visit the Emerald Guitar factory on November 16. This would allow an opportunity to experience a day’s visit to the shop during a trip that was otherwise emotionally heavyhearted.

After arriving in Dublin and scattering my dad’s ashes on November 11th, I arrived in Letterkenny, Donegal (just outside Johnston, Donegal where Emerald Guitars are located) on the 15th to spend the night and then the next day on the 16th. I texted Alistair to let him know I was staying the night in Letterkenny and to confirm for the following day. Much to my surprise, Alistair shared it was his 21st wedding anniversary. After chatting, Alistair said he would touch base with his wife about meeting with me in the evening for dinner. Alistair and I met in Letterkenny, had dinner, and discussed a wide array of topics aside from guitar, which was fantastic. That really got my mind out of a lot of things. When our discussion did turn to guitar, Alistair shared that he and his team spent a couple of weeks working overtime to complete the guitar and that it was done. I was surprised to learn the guitar was actually completed, as well as the other instrument I had commissioned. Alistair let me know the guitar actually had five outputs and they had taken liberty with the design. I confessed I had wanted to ask, on several occasions, to see photos of the build in progress. However, given everything going on, and my trust in his custom work, I did not feel the need to “check in.” Had I known Alistair and the team were working towards a full completion and unveiling for my trip, I may not have been able to resist. In retrospect, I am extremely grateful I was unaware the entire build was being completed for my visit and that I did not see any photos of the build in progress.

After arriving in Dublin and scattering my dad’s ashes on November 11th, I arrived in Letterkenny, Donegal (just outside Johnston, Donegal where Emerald Guitars are located) on the 15th to spend the night and then the next day on the 16th. I texted Alistair to let him know I was staying the night in Letterkenny and to confirm for the following day. Much to my surprise, Alistair shared it was his 21st wedding anniversary. After chatting, Alistair said he would touch base with his wife about meeting with me in the evening for dinner. Alistair and I met in Letterkenny, had dinner, and discussed a wide array of topics aside from guitar, which was fantastic. That really got my mind out of a lot of things. When our discussion did turn to guitar, Alistair shared that he and his team spent a couple of weeks working overtime to complete the guitar and that it was done. I was surprised to learn the guitar was actually completed, as well as the other instrument I had commissioned. Alistair let me know the guitar actually had five outputs and they had taken liberty with the design. I confessed I had wanted to ask, on several occasions, to see photos of the build in progress. However, given everything going on, and my trust in his custom work, I did not feel the need to “check in.” Had I known Alistair and the team were working towards a full completion and unveiling for my trip, I may not have been able to resist. In retrospect, I am extremely grateful I was unaware the entire build was being completed for my visit and that I did not see any photos of the build in progress.

The next day, I got lost heading out to the shop (my GPS was sending me to an entirely different county in Ireland based on the zip code!). Alistair left the shop and somehow I drove to a gas station for directions and he was sitting in his car trying to contact me on his cell. I followed Alistair to the shop, got a tour of the factory, and met the Emerald team over lunch.

During lunch, some guitars were passed out amongst the team, as well as myself. We played 1/4/5 blues and traditional Irish music as everyone finished up their meal. I got to meet Alistair’s wife Kim and son Dylan as well as the team. I also got to chat with Alan from the Emerald team several times during the day (and into the evening), as Alan does all their multimedia work and video recorded much of the day and took photos.

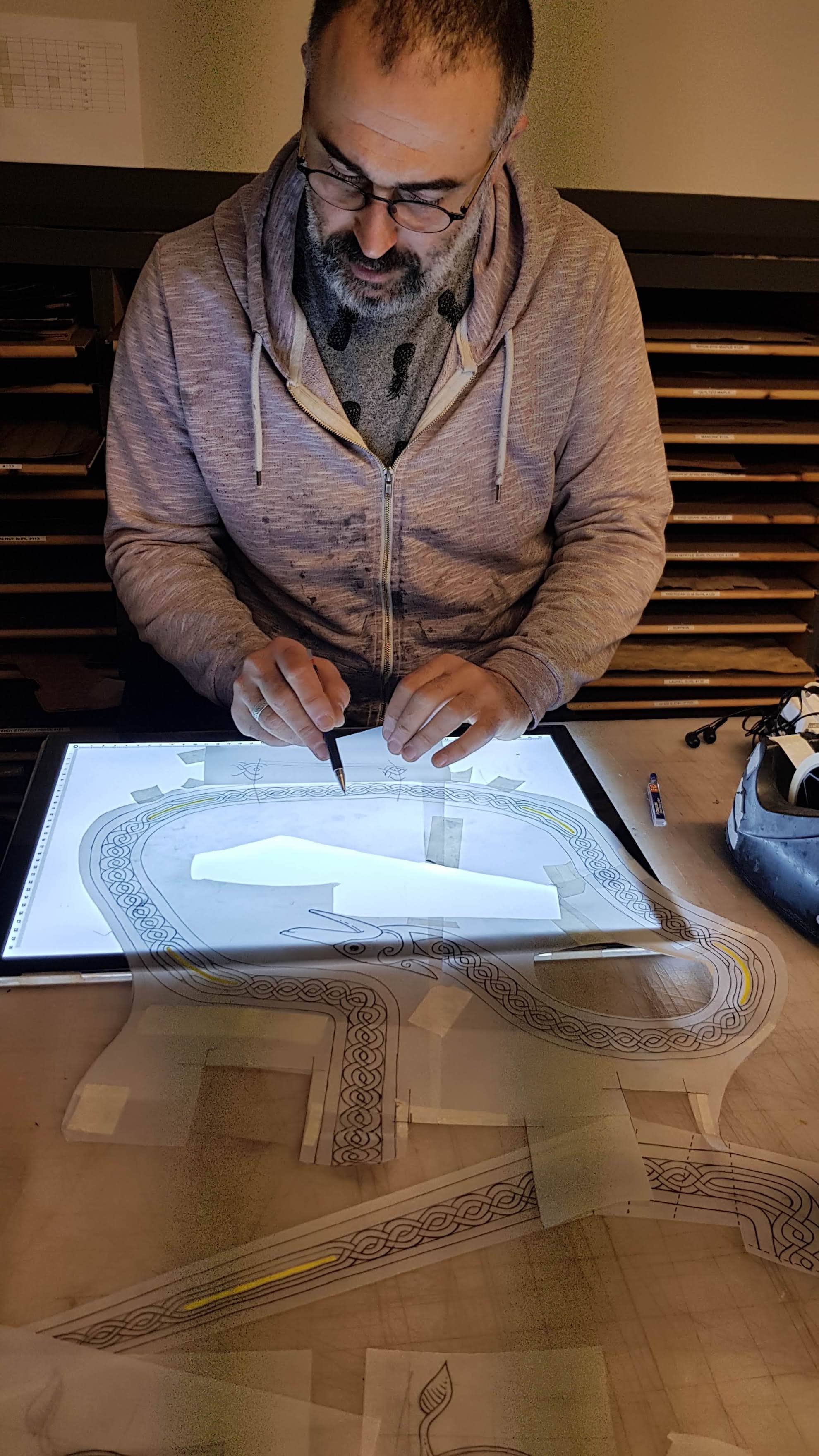

During lunch, all I could think about was seeing, playing, and hearing what turned out to be two completed builds rather then builds-in-progress. Before we left the larger lunch space to go to a viewing room for the unveiling, Alistair spoke about the build. He mentioned that the team really came together to complete the build after learning I would be visiting before the holidays. I learned that Shane was up until 1:00 a.m. putting the electronics together and setting up the instrument (that meant he was working on the guitar while Alistair and I were eating dinner the night before!). I also learned Franck put in a great deal of overtime completing the design, custom paint job, Celtic knot work, and Book of Kells artwork with calligraphy. Alistair also stated I needed to think of a name for the guitar, as a guitar build like the one they just completed deserved a proper name.

During lunch, all I could think about was seeing, playing, and hearing what turned out to be two completed builds rather then builds-in-progress. Before we left the larger lunch space to go to a viewing room for the unveiling, Alistair spoke about the build. He mentioned that the team really came together to complete the build after learning I would be visiting before the holidays. I learned that Shane was up until 1:00 a.m. putting the electronics together and setting up the instrument (that meant he was working on the guitar while Alistair and I were eating dinner the night before!). I also learned Franck put in a great deal of overtime completing the design, custom paint job, Celtic knot work, and Book of Kells artwork with calligraphy. Alistair also stated I needed to think of a name for the guitar, as a guitar build like the one they just completed deserved a proper name.

I got a chance to speak to the team and share my thanks for their efforts in what I was about to observe for the very first time. I shared with them how much I appreciated their talents, hard work, and hospitality. More specifically, I shared how I had noticed during dinner the night before and during the day that Alistair consistently speaks with “We” and not “I,” which in my opinion, is indicative of strong leadership.

When I shared I am not a guitar collector, I received a “collective” laugh, as I own a number of their instruments. I deserved that laugh, and as it turns out, Americans actually do get the humor in irony “across the pond.” I explained that everything I have ordered has been for specific purposes and use in writing and recording. I take great care of my instruments but they really are “turnkey” instruments for me that I love to use and play, not for collecting. I am not sure if I convinced anyone other than myself I do not have GAS (Guitar Addiction Syndrome) and I am not in need of a “12-fret program” but it was genuine! No one probably believed me, but I believed myself, which is important! I also apologized to Kim for Alistair and I having dinner on their anniversary (it WAS his idea) and I was relieved when I got a bit of a chuckle out of her.

As for the reveal, it was overwhelming. I need to confess I did not do the design or make decisions during fabrication. I cannot take any credit for that. I did not ask for the X10 Level 3 electronics on the 6-string neck, the team did that on their own. I asked for 3 outputs and got 5 – and I was thrilled. I loved the fact the controls were on the face of the guitar, which is where I would have asked for them given the X10 L3 electronics and other neck controls. This would have been my preference given the three guitar quarter-inch outputs, humbucker output, MIDI output, and switches. I would normally prefer no controls on the top of an acoustic but with the design and artwork, I loved how it fit in and I would have asked for it that way.

As for the reveal, it was overwhelming. I need to confess I did not do the design or make decisions during fabrication. I cannot take any credit for that. I did not ask for the X10 Level 3 electronics on the 6-string neck, the team did that on their own. I asked for 3 outputs and got 5 – and I was thrilled. I loved the fact the controls were on the face of the guitar, which is where I would have asked for them given the X10 L3 electronics and other neck controls. This would have been my preference given the three guitar quarter-inch outputs, humbucker output, MIDI output, and switches. I would normally prefer no controls on the top of an acoustic but with the design and artwork, I loved how it fit in and I would have asked for it that way.

The first thing I saw when I looked at the guitar was the inscription just under the 12-string neck on the soundboard, “M’athair, A Chuisle Mo Chroí,” which is Gaelic for, “My father, pulse of my heart.” I was in the room about two seconds when I read that inscription form the doorway and my eyes instantly welled up. It was really overwhelming and kind of embarrassing but I could not shut off my emotions. I remember noticing Alan was recording the unveiling and felt really aware of my emotions, which probably made it a difficult for everyone in the room but I was able to get it together as the unveiling progressed (I probably ruined the video recording but I couldn’t help it).

I was blown away by the Celtic knot work around the curve of the body through to the Irish wolfhound illustration (it also runs up the back of the 12-string neck). The colors looked fantastic and the inclusion of the torn parchment artwork Franck did actually looked three-dimensional. The detail work actually looks like real cracks on the surface of the instrument, which reflects true artistry and craftsmanship. In addition, when I got closer, I could see a great deal of time and effort went into adding the dark toning along the beveled edges and sides of the body. I liked how the dark edges tied into Emerald Guitars’ standard dark trim along the body corners and bevels. When I took a look at the back of the guitar, I was overwhelmed with the amount of detail and thought that went into the back design.

I was blown away by the Celtic knot work around the curve of the body through to the Irish wolfhound illustration (it also runs up the back of the 12-string neck). The colors looked fantastic and the inclusion of the torn parchment artwork Franck did actually looked three-dimensional. The detail work actually looks like real cracks on the surface of the instrument, which reflects true artistry and craftsmanship. In addition, when I got closer, I could see a great deal of time and effort went into adding the dark toning along the beveled edges and sides of the body. I liked how the dark edges tied into Emerald Guitars’ standard dark trim along the body corners and bevels. When I took a look at the back of the guitar, I was overwhelmed with the amount of detail and thought that went into the back design.

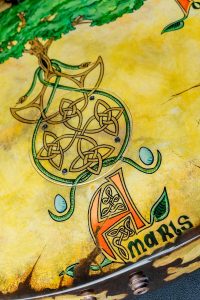

After looking at the back of the guitar for just a couple of seconds, it was apparent the team spent significant time and thought with respect to researching my family crest (from our Irish surname) and designing artwork with deep meaning for my wife, daughters, and me. Our Celtic family crest is a tree with two serpents intertwined around the trunk. At the roots of the tree, in Celtic script, Franck added the word Amaris, which is the name of my upcoming instrumental acoustic guitar album. Amaris has a variety of meanings, including “given by God” and “you are loved.” Amaris is also a combination of my wife’s name and my name (Amal and Chris). As I looked up from the roots, through the trunk, and into the treetop, the tree extends and “branched” out to our twin daughters’ names, Norah and Erin, with their names in Celtic script. I really loved the thought that went into the design and how it all tied into the guitar’s top inscription and concept.

In terms of how the guitar felt (or feels), it plays and sounds incredible. I immediately noticed a considerable amount of time and effort went into sculpting and beveling the top of the body leading to the mandolin neck. It felt much, much better than I thought it would and the beveling that went into the back, top, and arm rest were not elements I asked for but Alistair was mindful to include (I was not expecting that). In addition, the top sound hole has a different shape compared to the traditional Chimaera body as a result of the special carving. There was obviously a lot of thought that went into the ergonomic design of the guitar body to accommodate the third, upper neck for the mandolin.

In terms of how the guitar felt (or feels), it plays and sounds incredible. I immediately noticed a considerable amount of time and effort went into sculpting and beveling the top of the body leading to the mandolin neck. It felt much, much better than I thought it would and the beveling that went into the back, top, and arm rest were not elements I asked for but Alistair was mindful to include (I was not expecting that). In addition, the top sound hole has a different shape compared to the traditional Chimaera body as a result of the special carving. There was obviously a lot of thought that went into the ergonomic design of the guitar body to accommodate the third, upper neck for the mandolin.

I also noticed the team added the pinless bridge system for each bank of strings. Alistair stated that during the design they thought, aesthetically, the guitar would look much better with the pinless system and not distract from the artwork. I was actually happy they incorporated the pinless system and once again appreciated the thought and detail that went into the design.

I was able to play the guitar a few times during the afternoon but I honestly did not want to put the guitar down. When Alistair asked me to let him know when I choose a name for the guitar, I instantly responded with, “Trinity.” My thoughts were Trinity was an appropriate name for the guitar given it is a triple neck and in honor of my wife and two daughters. In addition, the inclusion of our family crest and dedication to my father was all centered around the Book of Kells, which is housed at Trinity College (I had just come from Dublin and visited Trinity College on the 14th). This all felt very much in line with the name of my upcoming 2019 album Amaris and theme for the artwork. Alistair also pointed out there is actually a Trinity knot on the face of the guitar, which I had seen but not tied into the name “Trinity” until that point. The way the whole guitar came together made me feel Trinity was absolutely the appropriate name for this instrument.

I was able to play the guitar a few times during the afternoon but I honestly did not want to put the guitar down. When Alistair asked me to let him know when I choose a name for the guitar, I instantly responded with, “Trinity.” My thoughts were Trinity was an appropriate name for the guitar given it is a triple neck and in honor of my wife and two daughters. In addition, the inclusion of our family crest and dedication to my father was all centered around the Book of Kells, which is housed at Trinity College (I had just come from Dublin and visited Trinity College on the 14th). This all felt very much in line with the name of my upcoming 2019 album Amaris and theme for the artwork. Alistair also pointed out there is actually a Trinity knot on the face of the guitar, which I had seen but not tied into the name “Trinity” until that point. The way the whole guitar came together made me feel Trinity was absolutely the appropriate name for this instrument.

After leaving Emerald Guitars for the day, Alistair and the team continued setting up the guitar and completing final details. I was really excited to receive the guitar, but given the holiday season, the guitar got stuck in NY customs for a couple of weeks. I actually received the guitar the day after Christmas (three weeks shipping time) and was relieved when it finally arrived.

I had to wait a couple of weeks before spending too much time playing the guitar due to having surgery on my left hand (my fretting hand). That whole situation is quite another story, but my mobility has almost fully returned. I got to finally record with Trinity for the first time on January 23, 2019 for inclusion on Amaris, which I am hoping to have completed for release in spring, 2019.

I also received a second instrument on the trip, an Amicus/Bouzouki Chimaera, which I will share at another time without the enormous back-story, as some aspects of that instrument build were already included.

I would like to thank the Emerald team for their design and work:

Alistair – Lead custom shop builder

Gareth – Molding and putting the carbon fiber structure together

Gavin – Fretting and prep-work

Franck – Artwork

Robbie – Clear coating

Steve – Polishing

Simon – Polishing

Shane – Electronics, pickups, and setup

Alan – Photographs/multimedia

Kevin – Always being responsive whenever contacted